- Your cart is empty

- Continue Shopping

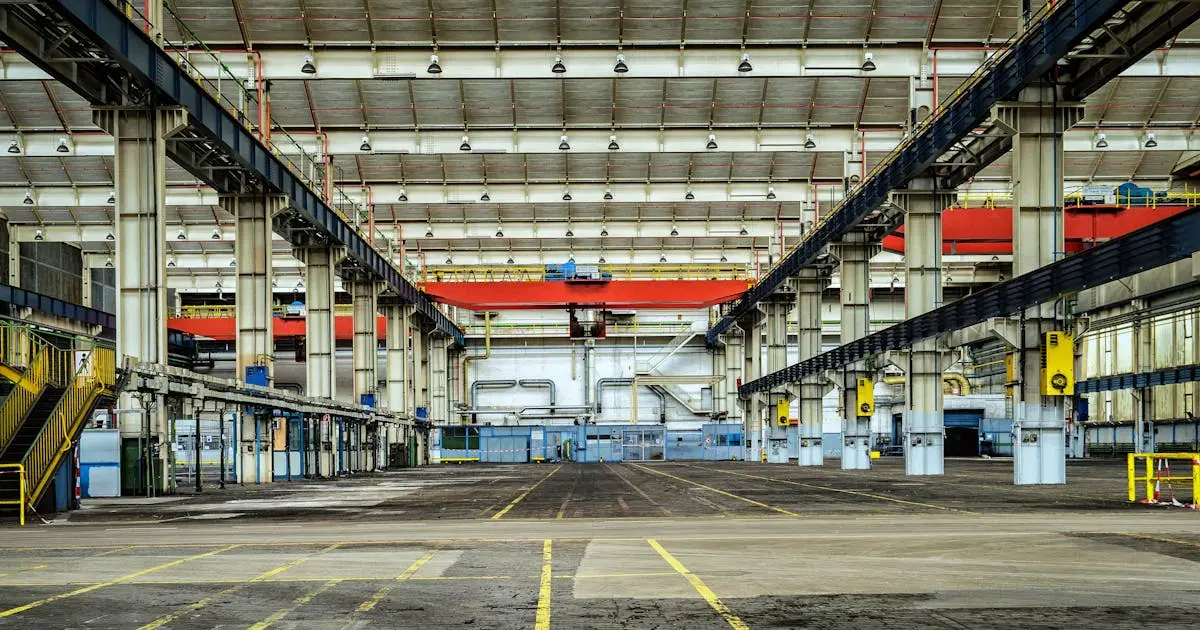

7 Best Warehouse Optimization Tips

If you want to make your warehouse more efficient and productive, you’ve come to the right place. In this article, we’ll explore seven warehouse optimization tips that can help you optimize your warehouse operations and maximize your resources.

1. Making the Most of Your Space for Warehouse Optimization

Getting Vertical

Instead of spreading out horizontally, consider utilizing vertical space by investing in tall shelving units or mezzanines. This can significantly increase your storage capacity without the need for extra floor space.

Stack It Up

Stack racks are a useful solution for storing objects vertically while keeping accessibility. Whether it’s pallets or irregularly shaped goods, stack racks can help you make the most of your warehouse space.

2. Smart Inventory Management

Harnessing RFID

Investing in Radio Frequency Identification (RFID) technology permits you to track your inventory in real-time, reducing mistakes and improving visibility throughout your warehouse.

Embracing Software Solutions

Applying inventory tracking software can modernize your inventory management processes, from tracking standard levels to estimating demand.

3. Streamlining Your Processes

Lean Principles

By applying lean values such as 5S and just-in-time inventory management, you can remove waste and enhance workflows in your warehouse.

Automation

Consider automating repetitive tasks with conveyor systems, robotic pickers, or AGVs to increase effectiveness and decrease labor costs.

4. Investing in Your Employees

Continuous Training

Offering constant training programs ensures that your employees are prepared with the skills they want to shine in their roles.

Valuing Feedback

Encouraging employee feedback fosters a culture of continuous improvement and innovation within your warehouse.

5. Prioritizing Safety

Regular Inspections

Regular inspections of equipment and facilities help identify potential hazards and ensure compliance with safety regulations.

Providing Proper Equipment

Equipping your employees with the right safety gear and ergonomic equipment is essential for preventing injuries and maintaining a safe working environment.

6. Optimizing Your Layout

Analyzing Flow

Take a closer look at the flow of goods within your warehouse optimization layout design and minimize travel distance for your employees.

Minimizing Travel

Grouping related items and optimizing storage locations based on picking frequency can help reduce travel time and improve efficiency.

7. Embracing Sustainability

Reducing Waste

Implementing waste reduction initiatives such as recycling programs and energy-efficient lighting not only benefits the environment but also saves costs.

Eco-Friendly Packaging

Opting for sustainable packaging materials helps minimize environmental impact and reduces packaging waste in your warehouse.

Conclusion

By implementing these seven warehouse optimization tips, you can optimize your warehouse operations, increase efficiency, and achieve sustainable growth in today’s competitive market.